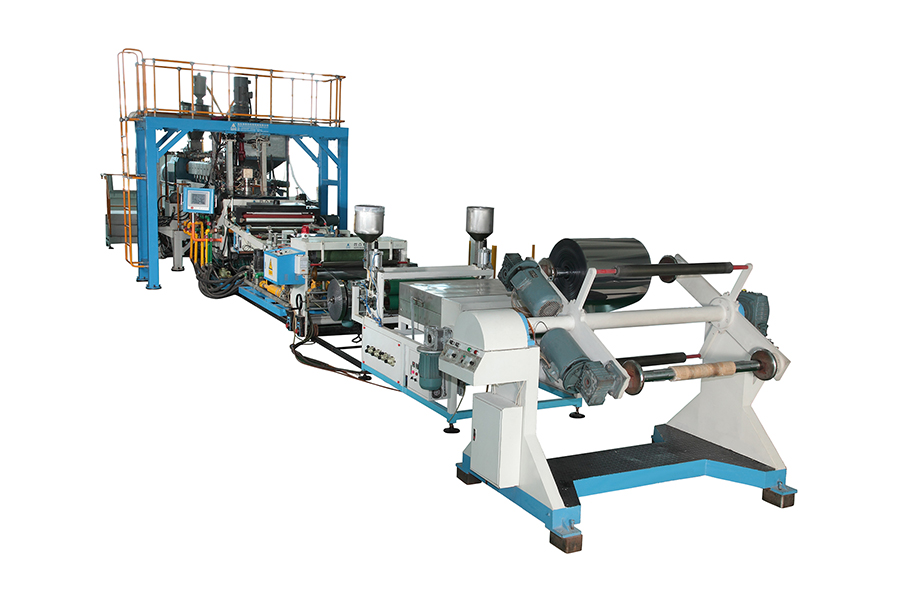

Lafoa'i Lafoa'i Fa'aula'i Fa'ama'i Lua (Pet Sheet Extruder)

Fua Fa'atekinisi

WJP(PET)75B-1000 Twin Screw Palasitika Extruder (PeT Sheet Extruder)

| Mea fa'aoga | Fa'amatalaga fa'amau | Mafiafia laupepa | Laulau lautele | Lafoa'i gafatia | Fa'apipi'i gafatia |

| mm | mm | mm | kilokalama/h | kW | |

| APET, PLA | Φ75 | 0.18-1.5 | ≤850 | 300-400 | 280 |

Vaega

1.O le elemene sikulima faʻaaogaina ituaiga faʻapipiʻi faʻalua filo faʻailoga faʻatasi ma le mamanu faʻaogaina komepiuta ma le saʻo machining. E le gata i lea, o le sikulima ua mamanuina i le faʻaogaina o le tuʻufaʻatasiga faʻapitoa, lea e sili atu le faʻamamaina o le tagata lava ia ma le fesuiaʻiga.

2. Faʻavae i luga o le tele o tausaga o faʻataʻitaʻiga faʻasologa o le faʻaogaina o le sikulima, e mafai e le AUTO ona faʻatinoina le faʻaogaina lelei o elemene faʻapipiʻi faʻatasi ma le fesoasoani a tekinolosi polokalama. O le mea lea, e mafai ona iloa le tuʻuina atu o mea faʻapipiʻi, faʻafefiloi faʻafefiloi, faʻafefeteina ma faʻasalalau, homogenization, volatilization ma devolatilization, tausia le mamafa ma le extrusion ma isi galuega e tusa ai ma mea a tagata faʻatau ma tekinolosi gaosiga.

3. O le paelo masini ua mamanuina ma ni feso'ota'iga vaivai e lua e fa'amautinoa ai le fa'amalo atoatoa o le ausa vai ma isi kasa fe'avea'i.

4. O le extruder palasitika sikulima masaga ua mamanuina ma liusuavai dosesing pamu mautinoa quantitative galuega faatino ma le mamafa tumau, lea e mafai foi ona fesoasoani i le iloa otometi tapunia-matavi pulea o le mamafa ma le saoasaoa.

5. O le aofaʻiga o masini faʻaaogaina le PLC faʻatonuina o le faiga, lea e mafai ona iloa ai le faʻatonuina otometi mo le faʻatulagaina o parakalafa, aso faʻagaioiga, manatu faaalia, mataʻutia ma isi galuega.

Fa'amanuiaga

O se tasi o mea taua tele o la matou masini fa'apipi'i palasitika masaga o latou elemene sikulima. Ua matua'i fa'aeteete ina ia fa'amautinoa le maualuga o le lelei ma le tumau e ala i le fa'aogaina o se sikulima lua-lele fa'atasi. O lenei mamanu tulaga ese ua tuʻufaʻatasia ma tekonolosi faʻaogaina komepiuta ma le faʻaogaina saʻo, e maua ai le faʻatinoga sili atu. O elemene sikulima o loʻo faʻaalia ai foʻi se fausaga faʻapitoa mo le faʻamamaina sili atu o le tagata lava ia ma le fesuiaʻiga. O lenei mea e faʻamautinoa ai se faʻagasologa lelei ma le le faʻalavelaveina o le gaosiga, faʻaitiitia taimi faʻaletonu ma faʻateleina le gaosiga.

O le tele o tausaga o le poto masani i le mamanu faʻapipiʻi sikulima e mafai ai ona matou faʻaleleia atili le faʻatinoga o le extruder. Faatasi ai ma le fesoasoani a tekinolosi faʻatekonolosi pito sili, e mafai ona matou faʻapipiʻi lelei faʻapipiʻi elemene elemene. O lona uiga e mafai e a tatou extruders ona faʻafeiloaʻi lelei ma faʻapipiʻi meafaitino, faʻamautinoa se tulaga maualuga maualuga. O a matou tekonolosi faʻapipiʻi e taua tele i le ausiaina o tulaga sili ona lelei, faʻamautinoaina o matou tagata faʻatau e mafai ona gaosia le tulaga maualuga o le PET pepa.

O le isi fa'amanuiaga taua o la matou masini fa'apipi'i palasitika masaga sikulima o lo latou agava'a. Pe o loʻo e gaosia le PET pepa mo le afifiina, thermoforming poʻo soʻo se isi lava talosaga, e mafai e matou extruders ona faʻafetaui ou manaʻoga tulaga ese. E mafai ona gaosia le tele o meafaitino eseese, e maua ai le sili atu le fetuutuunai i lau gaioiga gaosiga. E le gata i lea, o matou extruders ua mamanuina mo fetuunaiga faigofie ma vave, e mafai ai ona e faigofie ona fesuiaʻi i le va o ituaiga oloa eseese. O lenei agavaʻa e faʻasaoina ai oe taimi ma tupe, faia a matou extruders o se fofo taugofie mo au mea e manaʻomia ai lau PET.